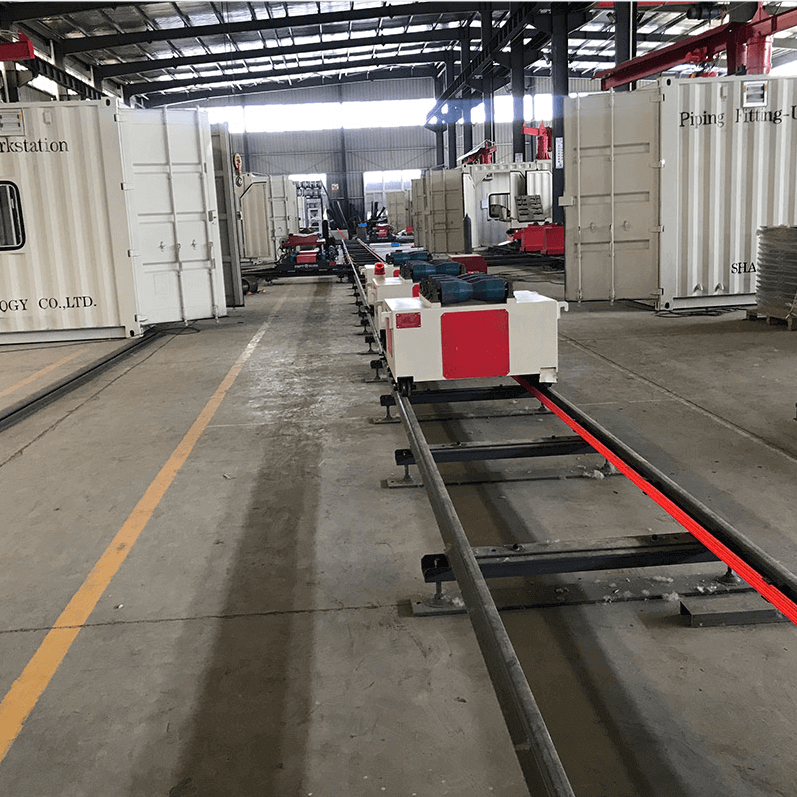

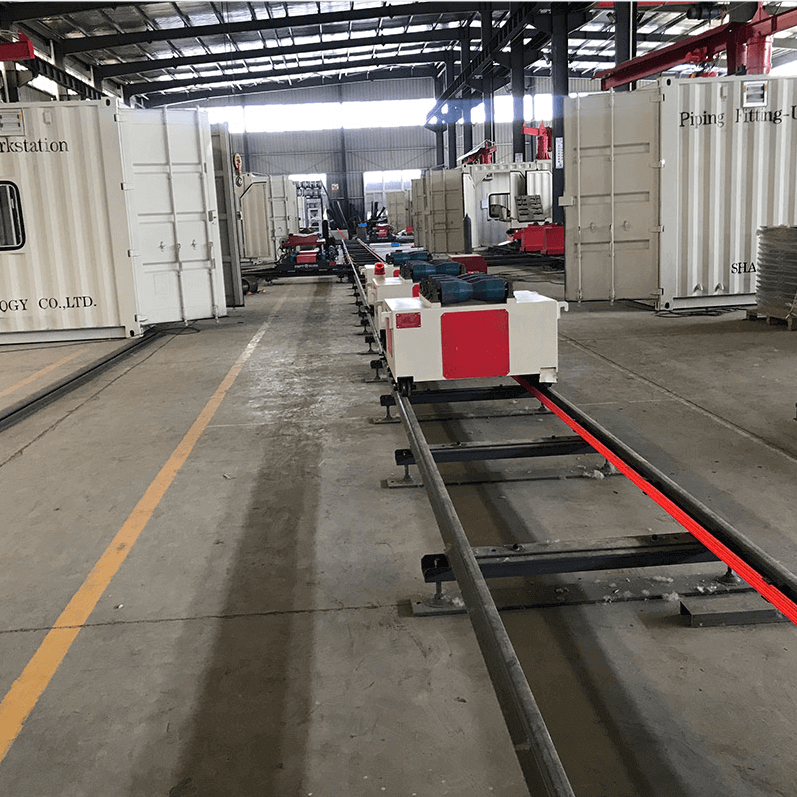

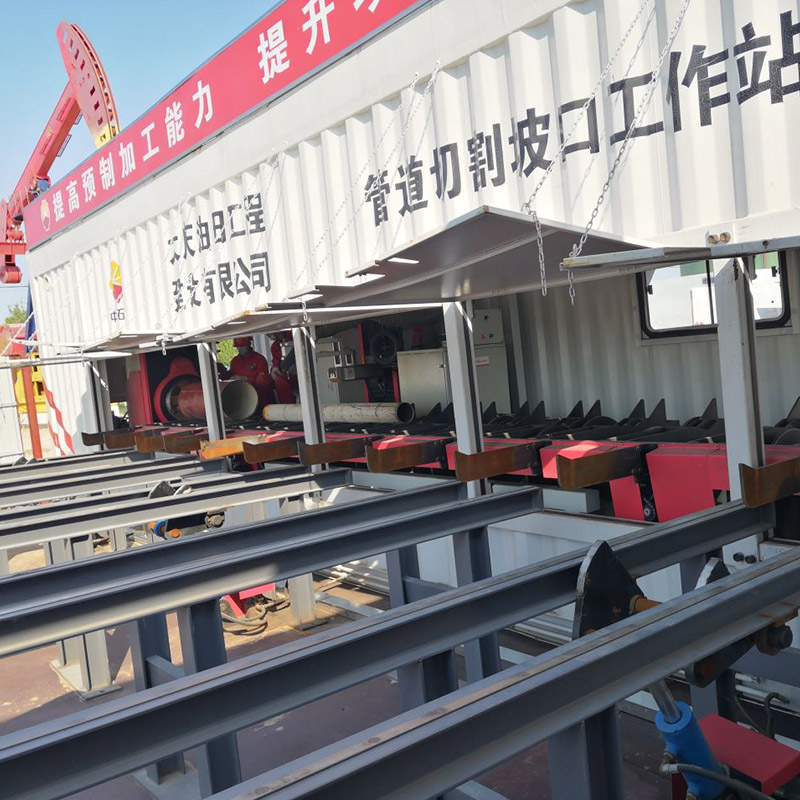

The basic configuration of the pipe cutting and beveling workstation consists of one set of 6m containers made with special retrofit, one set of high-speed pipe cutting band saw machines, one set of fixed-type high-speed pipe end beveling machines; three sets of a bracket supporting trolley or three sets of rail and trolley conveying system or one set of roller conveying system for band saw machine +1 set of conveying system for end beveling machine and 1 set of piping cantilever crane (option).

1. The production capacity of the pipe cutting and beveling workstation is cutting speed: ≤2 min/pipe, and beveling speed: ≤5 min/pipe bevel (DN200 SCH40).

2. It offers excellent mobility (without limitation of radiation radius when using container as carrier).

3. The bevel quality is good.

4. Classical type; Specialized field work station. CNC cutting to length; Beveling quality reaches cold machining level; Suitable for beveling all kinds of pipes, especially stainless steel pipes and thick-wall pipes. Equipped with: one specially retrofitted 6M container + one High-Speed Pipe Cutting Machine/CNC Pipe Cutting Band Saw Machine + one High-Speed Pipe End Beveling Machine/CNC Pipe End Beveling Machine.

Pipe Diameter Applicable: DN400/DN600

Pipe Wall Thickness Applicable: 4~90/5~180MM

Applicable Materials: Carbon steel, alloy steel, stainless steel, and cryogenic steel

Cutting Length: Unlimited

Bevel Shape: U, X, V, and double Vs, etc.

Max. Lifting Weight: 1 ton

Conveying System: Each bracket supporting trolley is provided both at the pipe input and output side of the band saw machine; a crane is used to get the pipes in or take them out; a bracket supporting trolley is provided at the feed-in/out end of the beveling machine and gets the pipes in or takes them out of the bracket and beveling machine by crane truck or cantilever crane. A rail and trolley conveying system or a pipe roller conveying system for end beveling machine with a lifter shall be mounted in front of the beveling machine to automatically adjust the elevation of the pipes to bevel the pipes of different diameters if required, or two rails and trolley conveying system or a set of roller conveying system for band saw machine can be equipped for feed-in end or feed out the end of the band saw machine.

Length-Measuring System: A mechanical pipe cutting length-measuring system can be provided if necessary to measure the length of the pipes as well as cut and bevel them in cooperation with the roller conveying system (option).

The pipe cutting and beveling workstation are used for cutting and beveling of the pipes with heavy wall thickness.

After-Sale Service Guideline: ” Worry what users worry, think what users think ”

Within/beyond the warranty period, when the equipment gets out of order or is damaged, the company will provide technical consulting services without or with a charge. For customer advisory, the company will supply responses on the phone within 4 hours and written replies within 8 hours. If the customer requires, within 24 hours (within the distance of 800 KM) or within 48 hours (above 800 KM), the company will dispatch experienced engineering technical personnel to the customer site to analyze and guide maintenance. They will not leave until the fault is cleaned and the customer is satisfied.